Melting and holding furnaces are the solution to create autonomous work islands, without the need to use a melting furnace to feed the island itself.

Melting & Holding

MARCONI melting and holding furnaces are built with the following strengths:

- Wide and deep load/preheating dry soles

- Automatic doors for loading and cleaning

- Patented basin shape without corners: facilitates cleaning operations and prevents slag buildup

- Flame with automatic controlled combustion: high production with a significant reduction of oxides and extremely low consumption

- Basin for holding molten aluminum with more constant temperatures

- Patented removable vault that allows for easy internal maintenance

- Positioning capability in complex layouts thanks to the possibility, during construction, to orient the tapping spout over a 180° arc relative to the charging mouth

- All models come standard equipped with SIEMENS PLC and color eTouch screen Special Marconi software with alarm pages, furnace status, possibility of connecting to your company network for data management, and connectivity to our operational center for remote and direct assistance

- Special executions for alloy change and degassing in aluminum bath

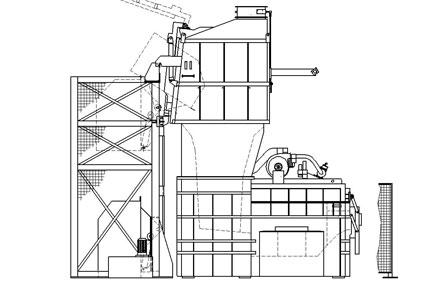

MTXB Furnace

TECHNICAL INFORMATION

- Capacity: from 1,000 to 2,000 Kg

- Production: 600 / 1200 Kg/h

NEED ASSISTANCE? CONTACT US TO RECEIVE MORE INFORMATION

CLICK HERE